Last month we worked with a client named Anton to create this complex, fashionable and functional watch! Anton has been creating products for 5 years. He designs watches, cufflinks, rings, bowties, clothing, furniture, installations, and completes custom work. He explains, “I don’t have an Industrial Design background. I am just a guy that likes to put my own cool spin on everyday things.”

Anton’s adoration for horological machines is inspired by the companies Urwerk and MB&F. His motto that he excitedly shared with us is #designdonedifferent. This philosophy is evident in his watch, “PH Carina”, created with 3DPhacktory’s printers and design help. Anton tells us that “3D printing is fabulous – it is so beneficial for both prototyping AND creating finished products.”

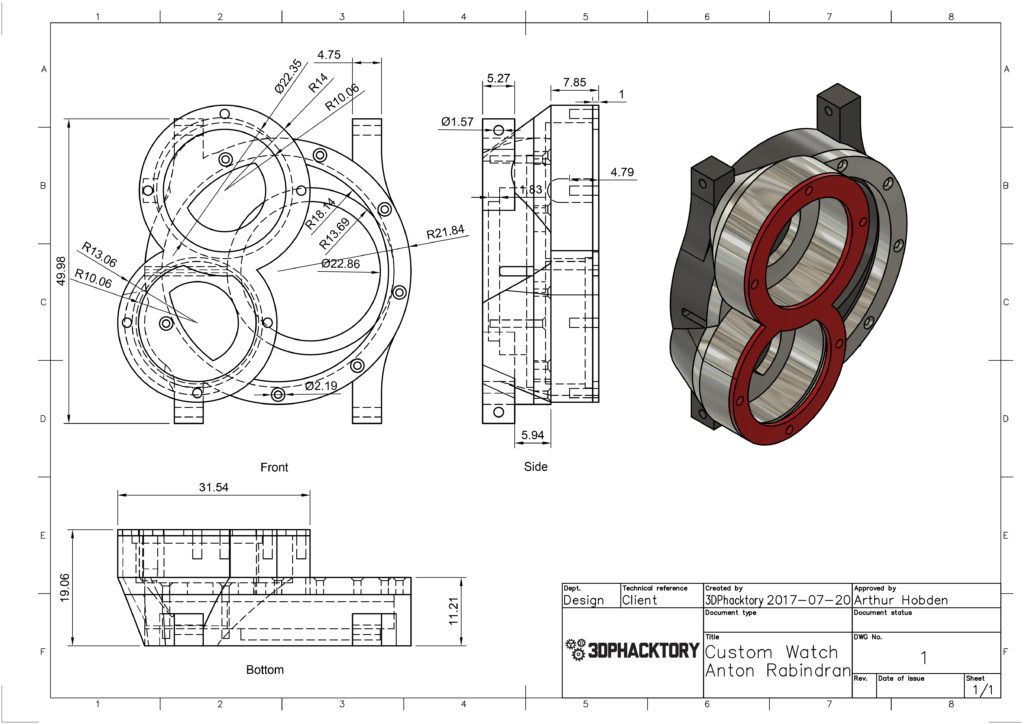

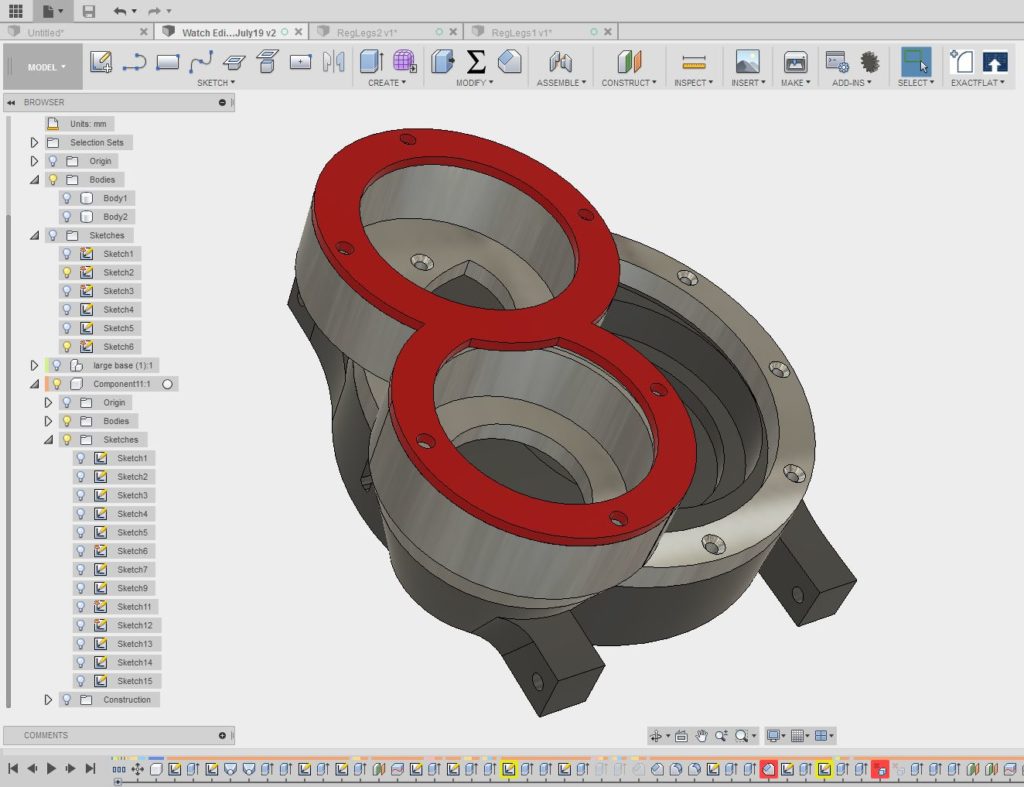

Anton brought us a partially completed 3D file, which he then worked with our designer, Arthur, to perfect and finalize using 3D modeling software called Fusion 360.

Anton’s custom watch consists of his own moving parts that he found and a Vero white plastic frame, printed on the Connex500. After the frame was 3D printed, Anton was able to paint and assemble the watch himself. Anton explains that this watch is very important to him because it is something that he wants to push into the industry!

Check out and support Anton’s wonderful creations:

twitter and instagram: @hwritesdesign